Excellent fire resistant property for Welding clothing and apron

KANOX® G

KANOX G

In addition to its heat resistance KANOX-G also protects well against molten metal splashes, making it especially suitable for all-around welding protection. The fabric is widely used in Steel Industry, Petrochemical Industry and Refinery Industry, it is suitable as a material for single-layer welding suit, welding apron and welding workwear.

The main composition of KANOX-G is oxidized fiber, which is design for flame and heat resistance solution, then blend in Para-aramid fiber to increase the strength of the fabric. To combine two of these fibers, the important characteristic on KANOX-G include excellent flame and heat dimensional stability, passing the impact of molten metal drops test, having soft and comfortable properties. Other performances of this fabric are electrically nonconductive, good chemical resistance and low toxic gas emissions.

Available color is Dark Green.

Application

- Welding Apron

- Protective Clothing for Welding industry, Metallurgy industry, Cement industry, Steel refinery

Product Description

Specification - Weave : Twill or Ripstop - Weight : 280 g/m² - Width : 150 cm - Color : Dark Green

Norm

- EN531 Flame spread

- EN470 Heat resistance

Materials

- Pan-Oxidize / Aramid

- Related Products

The Ultimate Firefighter's Fabric made of PBO and Aramid strong fibers

KANOX® PBO PIONEER

Experience the pinnacle of safety and performance with KANOX PBO Pioneer, a groundbreaking fabric engineered to protect firefighters in the most demanding environments. Composed of a meticulously crafted...

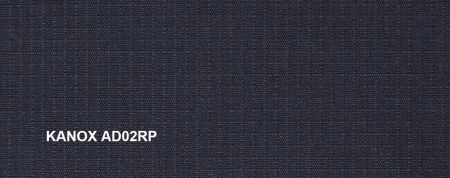

DetailsLight Weight 240gsm but High Tear Strength Outer Shell for Heavy Duty Firefighting Suit

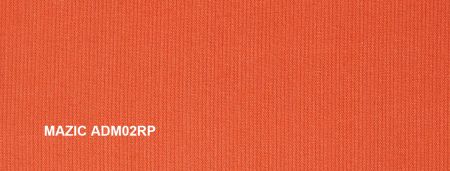

KANOX® AD02RP

KANOX AD02RP, a groundbreaking fabric renowned for its exceptional durability and performance in firefighting gear. While its colors may not boast the same vibrancy as those achieved through piece-dyeing,...

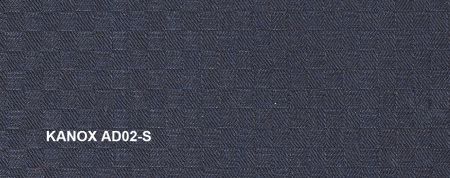

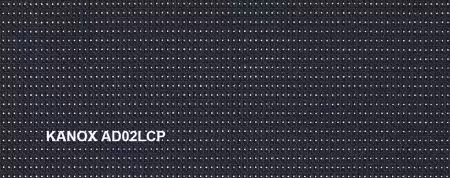

DetailsJacquard Weave Reinforcement with great Abrasion Resistance and Color Design

KANOX® AD02LCP

KANOX AD02LCP are basically same as KANOX AD02RP in materials. The main difference between KANOX AD02LCP and KANOX AD02RP is its variety of colors resulted from Jacquard weave. Feature of jacquard fabric...

DetailsNeedle Punch or Spunlace Thermal layer made of aramid or oxidized fibers

KANOX® GORNOX / KANOX® NW / MAZIC® F90SL

The KANOX GORNOX and KANOX F90SL series serve as the middle layer in protective garments or personal protective equipment (PPE). Both series are made from 100% aramid non-woven fabric, which provides excellent...

DetailsMeta aramid 93% Para aramid 5% Antistatic 2% ready in both twill and ripstop weaves

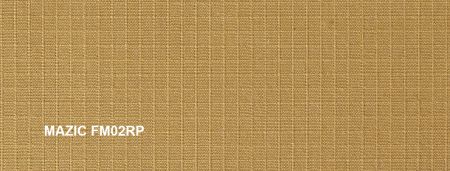

MAZIC® FM02

MAZIC FM series is a versatile lineup of protective fabrics designed to meet the diverse needs of firefighters and industrial workers alike. Comprised of 93% Meta aramid, 5% Para aramid, and 2% Antistatic...

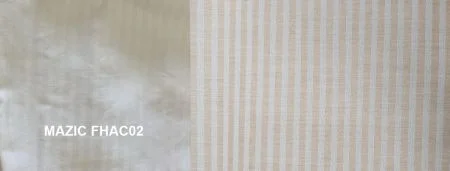

DetailsFlame Retardant Fabric with Cotton inside, colorful Twill or Ripstop for uniforms

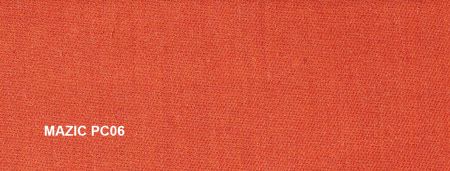

MAZIC® PC06 / MAZIC® PC06RP

MAZIC PC06 series is a mixture containing cotton, making it one of the most comfortable and breathable among FR fabrics. Even so, the fire resistant properties of Mazic PC06 series surpass European Standard...

DetailsInterlock or Rib knit with ultralight breakthrough in multi-protection

MAZIC® FM02K / MAZIC® F100K / MAZIC® PC02K / MAZIC® AC02K

MAZIC knit fabrics are inherently fire resistant due to aramid fiber blended. The other blend-in fibers are modacrylic, cotton, or antistatic subject to the performance we expect for. MAZIC knit fabrics...

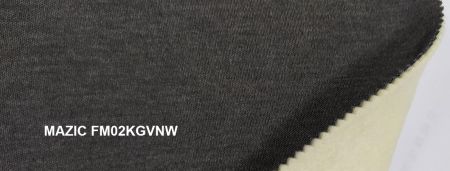

DetailsThermal inner lining in the form of knitted laminated non-woven at weight 500gsm

MAZIC® FM02KGVNW

MAZIC® FM02KGVNW is laminating fabric - knitted fabric laminated with non-woven fabric. No doubt of its fire resistant performance because of aramid fiber the major ingredient. The side of knitted...

Details

To be a global performance leader for firefighting suits and inherently fire resistant fabrics.

How Can Steel Plants Ensure Maximum Worker Safety During High-Temperature Welding Operations?

KANOX-G fabric with over 50% oxidized fiber content provides certified protection against molten metal splashes and extreme heat exposure, meeting EN531 and EN470 standards. Our vertically integrated manufacturing ensures consistent quality and reliable performance for your workforce. Contact us to receive technical specifications and sample materials tailored to your steel manufacturing safety requirements.

Certified to EN531 for flame spread resistance and EN470 for heat protection, KANOX-G demonstrates superior performance characteristics including electrical nonconductivity, excellent chemical resistance, and low toxic gas emissions. The dark green fabric is available in 150 cm width, providing versatility for various protective garment configurations. Taiwan K.K. Corporation's vertical integration ensures consistent quality from fiber production through finished fabric, delivering reliable protection solutions that meet the rigorous safety demands of metallurgy, cement manufacturing, and steel refinery industries worldwide.