KANOX® - Fabric Properties

KANOX® Series

-

Product Information

- Provides high performantce in firefighting when every second counts.

- Uses unique blend of acrylinitrile oxide fiber and modern strengthening fiber to provide the highest level of protection against heat and flame.

- Fabrics combine superior performance with outstanding comfort.

- The property of inherent fire redidtance acts as the primary one if the fabric characteristics. KANOX® fabrics do not melt, ignite or drip when exposed to fire. Heat Insulation

- KANOX® fabrics provide excellent heat insulation. The fabrics can resist most of the heat and keep a relatively low temperature on the opposite side of the fabrics. Static Resistance

- KANOX® fabrics have a blanced moisture regain, which prevents the generation of static electricity, and makes the wearer feel comfortable. High Strength and Durability

- KANOX® fabrics are made of high strengthening fibers blended with fire resistant fibers, and achieve excellent property of Tensile and Tear strength. The armor-like fabrics help you to handle any unexpected situation. Diversified Colors Available

- KANOX® fabrics also achieve fine characteristics of color fastness. To satisfy various kinds of demands, diversified colors are available. Harmonious with Environment

- KANOX® fabrics do not contain chemical adding or asbestos. They do not cause any allergic symptoms on your skin, and are harmonious with both human body and environment.

Outperforming Properties

Inherent Fire Resistance| Article No. | Specification | Features | Applications | Color in stock |

|---|---|---|---|---|

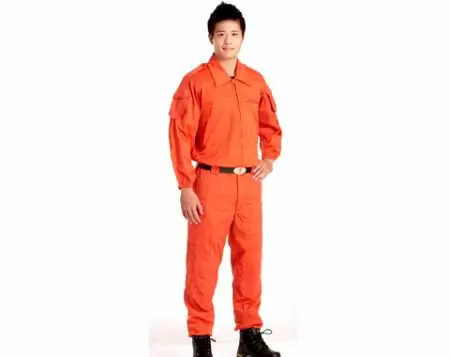

| AD02RP | 240g/m², Ripstop, Anti-static | High strength. Excellent heat resistance. Good abrasion resistance. | Outer shell of fireman suit. Rescue suit | Navy Blue, Royal blue, Orange, Yellow, Red |

| AD02LCP | 260g/m², Jacquard weave | High strength. Excellent heat resistance. Good abrasion resistance. Innovative color & pattern | Outer shell of fireman suit. Reinforcement. Palm abrasion of Gloves | Navy Blue with white dots, Orange with white dots |

| HM02RP | 240g/m², Ripstop (or Twill) | High tear/tensile strength | Outer shell of fireman suit. Rescue suit. Anti-riot coverall | Navy Blue, Royal Blue, Yellow, Orange, Red |

| KANOX-G | 280g/m², Twill, Pan-oxidize & high strength fiber | Excellent flame & heat resistance. Resistance to metal splash | Welding suit | Dark Green; |

| TM02 | 210 g/m², Ripstop, Anti-static | Good flame & heat resistance | Anti-riot coverall. Industrial workwear | Black |

| GORNOX | 120 g/m², Non-woven | Good heat resistance | Thermal layer of fireman suit | Yellow |

| NW-3 | 400 g/m², non-woven felt type | Excellent heat resistance. | Fire Resistance Blanket | Black |

KANOX® and MAZIC® Fire Resistant Fabrics comply with EN531, EN470, EN ISO 11611, EN ISO 11612, ISO 15384, EN469, and/or NFPA1971.

More items of KANOX® and MAZIC® fabrics are available upon request.

Limited Oxygen Index (L.O.I.)

Flame resistance is commonly measured by the highest Limited Oxygen Index (LOI), the amount of oxygen needed to support combustion. The higher the LOI value the more flame-resistant the material is. KANOX® fabric has a LOI of over 50 that is much higher than other's.

Degradation Temperature

The degradation point is the point where the fabric loses its structural integrity and breaks open. The higher the score he better it is.

KANOX® has the highest degradation temperature, which means its traditional protection is also outperforming.

Infrared Rays Reflectance and Heat Insulaation Performance

Moisture Absorption

| Fabric | Moisture Absorption |

|---|---|

| KANOX® | 8~12 |

| Natural Silk | 12 |

| Cotton | 8.5 |

| Nylon | 4.5 |

| Polyester | 4.5 |

| Natural Wool | 15 |

| Rayon | 11 |

Thermal Protection Performances (TPP)

TPP are composite measures of four layers of turnout gear. the higher TPP value you see the higher thermal protection performance it is. NFPA 1971 norm requires a TPP value of no less than 35.

| - | PBI | NOMEX advance | KANOX® | NFPA 1971-2000 Req. |

|---|---|---|---|---|

| TPP | 46~48 | 41~43 | 45~47 | 35 |

Total Heat Loss (THL)

For THL the moisture barrier is the most important component. That means the fire fighters benefit form improved mobility and superior cooling without sacrificing thermal protection and comfort. The higher THL value you see the lower heat stress it is. NFPA 1971 norm requires a minimum THL of 130.

| - | PBI | NOMEX advance | KANOX® | NFPA 1971-2000 Req. |

|---|---|---|---|---|

| THL | 228~233 | 215~220 | 228~233 | 130 |

- Related Files Download